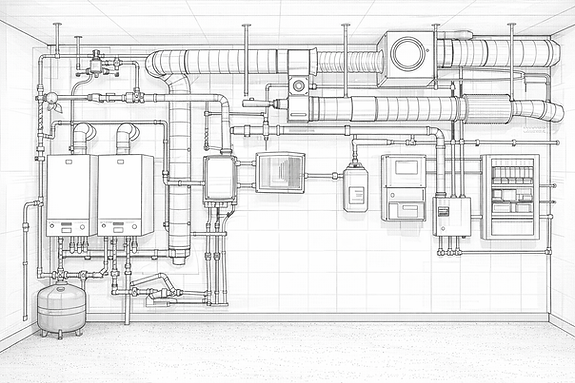

Commercial Plant Room Installations

Safe, Efficient, and Compliant Plant Room Solutions

At JLG Kitchens & Vent, we design and install commercial plant rooms to house ventilation systems, utilities, and service equipment safely and efficiently. Our solutions ensure compliance with regulations while supporting the smooth operation of your catering or hospitality facility.

Built to support everything else.

Commercial plant rooms are the backbone of a well-functioning catering operation. When designed and installed correctly, they allow essential systems to operate reliably, safely, and without disruption to kitchen or customer-facing areas.

Our plant room installations focus on practicality, access, and long-term performance, ensuring critical services are protected and easy to maintain.

Plant Rooms Designed for Commercial Catering & Hospitality

Plant rooms must safely accommodate mechanical and electrical systems while allowing for servicing, inspections, and future upgrades. We design plant rooms around the specific requirements of your building and installed equipment.

Our plant room design considerations include:

-

Safe housing of ventilation and extraction equipment

-

Clear access for maintenance and inspections

-

Logical organisation of services and controls

-

Adequate ventilation and heat management

-

Efficient use of available space

This structured approach helps ensure systems operate reliably without creating unnecessary risk or downtime.

Integrated Ventilation, Utilities & Safety Systems

Commercial plant rooms often house multiple critical systems. We coordinate installations to ensure all services work together efficiently and safely.

Our plant room installation services typically include:

-

Ventilation and extraction plant

-

Structural supports and access solutions

By integrating these elements, we help create organised, compliant plant rooms built for long-term use.

Installed for Safety, Compliance & Reliability

Correct installation is essential to ensure plant rooms meet safety and compliance expectations. Our team installs plant rooms with careful attention to spacing, access, and system integration.

We focus on:

-

Safe clearances around equipment

-

Secure mounting and fixing

-

Logical routing of services

-

Clear labelling and access points

-

Support for inspection and maintenance requirements

This attention to detail helps reduce risk and supports smooth operation throughout the life of the facility.

Suitable for New Builds, Refits & System Upgrades

We deliver commercial plant room installations for:

-

New catering and hospitality developments

-

Commercial kitchen refurbishments

-

Ventilation and system upgrades

-

Changes to equipment or operational capacity

Whether part of a full project or a standalone installation, our plant room solutions are tailored to suit your operational needs.

Commercial Plant Room Installations Across Essex, London & the M25

We provide commercial plant room design and installation services across Essex, London, Kent, and the wider M25 area, supporting restaurants, hotels, schools, care facilities, and catering operations of all sizes.

If you are planning a new plant room or upgrading existing systems, our team can provide clear, professional guidance from design through to installation.

Next step:

Contact our team to discuss your commercial plant room installation requirements and arrange a consultation.

Get a Quote

Ready to discuss your project?

Whether you need a full commercial kitchen installation or a specialist service, our team is here to help. Get in touch with JLG Kitchens & Vent for expert advice and a no-obligation quotation.

Frequently Asked Questions

Plant Rooms

What is a commercial plant room?

A commercial plant room is a dedicated space that houses essential building and kitchen services such as boilers, water heaters, ventilation equipment, refrigeration plant, pumps, control panels, and safety systems. It supports the operation of kitchens and other commercial environments behind the scenes.

Why are plant rooms important in commercial kitchens and buildings?

Plant rooms centralise critical equipment, improving safety, efficiency, accessibility, and maintenance. A well-designed plant room reduces noise and heat in working areas while ensuring systems operate reliably and compliantly.

What equipment can be installed in a plant room?

Plant rooms can house:

-

Boilers and water heaters

-

Ventilation and air handling units

-

Refrigeration plant and condensers

-

Gas safety systems and shut-off valves

-

Control panels and BMS interfaces

-

Pumps, filters, and pipework

Equipment selection depends on building use and system requirements.

What regulations apply to commercial plant rooms?

Plant rooms must comply with health & safety regulations, gas safety standards, ventilation requirements, fire safety guidance, and relevant building and M&E regulations. Correct access, clearances, and safe installation practices are essential.

What guidelines need to be followed in plant room installations?

Guidelines typically cover safe access, equipment spacing, ventilation, fire separation, drainage, isolation points, and maintenance access. Following these ensures safe operation and easier servicing.

How much space is required for a plant room?

There is no fixed size. Space requirements depend on the type and quantity of equipment, access needs, and future maintenance considerations. Proper planning ensures safe clearances and long-term flexibility.

Can safety systems be installed in plant rooms?

Yes. Plant rooms are ideal locations for safety systems such as gas shut-off valves, interlock panels, fire suppression controls, alarms, and monitoring equipment—keeping them accessible but protected.

Can you assess an existing plant room installation?

Yes. Existing plant rooms can be reviewed to assess safety, compliance, layout, and performance. This helps identify risks, inefficiencies, or upgrade opportunities.

Can you recommend improvements to an existing plant room?

Yes. Practical recommendations can be made to improve safety, efficiency, accessibility, and compliance—whether through equipment upgrades, layout changes, or additional safety systems.

What do you check during a plant room assessment?

Checks typically include:

-

Equipment condition and positioning

-

Ventilation and airflow

-

Safety systems and isolation points

-

Access and maintenance clearances

-

General health & safety risks

Can plant rooms support commercial kitchens and bars?

Yes. Plant rooms commonly support kitchens, bars, cafés, and catering facilities by housing shared systems such as hot water, extraction plant, refrigeration systems, and safety controls.

Can plant rooms be included in new builds?

Yes. Plant rooms can be designed and installed as part of new-build projects, ensuring systems are properly planned from the outset and fully compliant.

Can plant rooms be retrofitted into existing buildings?

Yes. Existing buildings can often be adapted to include or improve plant rooms, subject to space, access, and service availability.

How do I start a commercial plant room project?

The first step is a site survey and consultation. This allows equipment needs, space constraints, and compliance requirements to be assessed before design or installation.

Do you offer site surveys and quotations?

Yes. A free site survey and quotation is available to review your plant room requirements and outline costs before work begins.

How much does a commercial plant room installation cost?

Costs depend on equipment type, system complexity, space constraints, and installation scope. Investing in a well-designed plant room often reduces long-term maintenance and operational costs.

Do you work with M&E teams, facilities management, and engineers?

Yes. Plant room projects are regularly coordinated with M&E departments, facilities managers, engineers, and installers to ensure seamless integration with building services.

What are the benefits of a well-designed plant room?

Key benefits include improved safety, easier maintenance, reduced downtime, better system performance, and cleaner, quieter working environments in kitchens and occupied spaces.

What areas do you cover for commercial plant room installations?

Commercial plant room design, installation, assessment, and upgrade services are available across London, Essex, and inside and around the M25.

Why choose a specialist for commercial plant room installations?

Specialists understand complex building services, safety requirements, and long-term operational needs. This ensures plant rooms are compliant, efficient, and built to support everything else reliably.